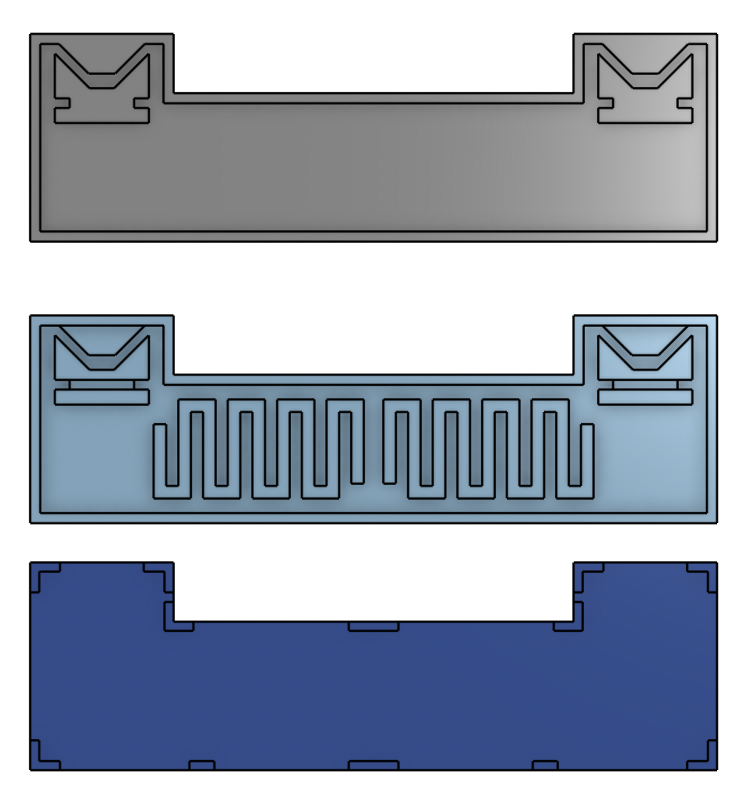

Soft Robotic Crawler — “Skippy”

Designed and built a bio-inspired soft robot capable of crawling using pneumatically actuated legs with anisotropic friction pads. Developed in Boston University’s Soft Robotics Lab to explore morphological computation and adaptable locomotion.

Boston University Soft Robotics Lab – ME568 Final Project

Co-developed with George Knight, Liam Thirtyacre, and Tanvi Shingade as part of ME568: Soft Robotic Technologies under Prof. Tommaso Ranzani.

Project: “Skippy” – A modular, bio-inspired crawler for adaptive terrain navigation.

Overview

Skippy is a soft robotic crawler that uses pneumatically actuated silicone legs and anisotropic friction “ski-skin” feet to traverse uneven terrain.

Skippy is a soft robotic crawler that uses pneumatically actuated silicone legs and anisotropic friction “ski-skin” feet to traverse uneven terrain.

The design draws inspiration from cockroach and turtle locomotion, where forward motion is achieved not by precision control, but by morphological computation — allowing the robot’s body and materials to do the thinking.

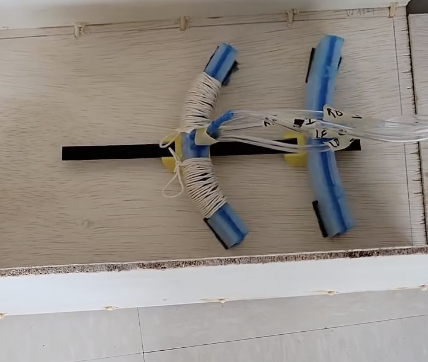

Right: Bird’s-eye view of Skippy showing the modular spine and paired leg actuators, And temporary fiber wrap support

Key Highlights

- Objective: Develop a fast, adaptable soft robot for rough terrain navigation

- Actuation: Pneumatic silicone legs with anisotropic ski-skin feet

- Structure: Flexible PLA spine with replaceable vertebrae and modular leg attachments

- Simulation: Abaqus modeling of leg deformation and foot inflation

- Performance: Achieved ~11 cm/s (≈1 body length/s) with basic open-loop control

- Material System: Dragon Skin 10 and Blue Sapphire silicone, cast via parameterized molds

Inspiration and Design Philosophy

Skippy’s design began with an analysis of cockroach locomotion studies, which revealed that efficient movement can emerge from body mechanics rather than complex control.

By using compliant silicone legs with friction-differentiated feet, Skippy “swims” across land like a small turtle or lizard.

Each leg’s shape and channel geometry were parameterized in CAD (OnShape) for rapid iteration, enabling redesigns for different terrains or gait experiments.

Leg Actuators

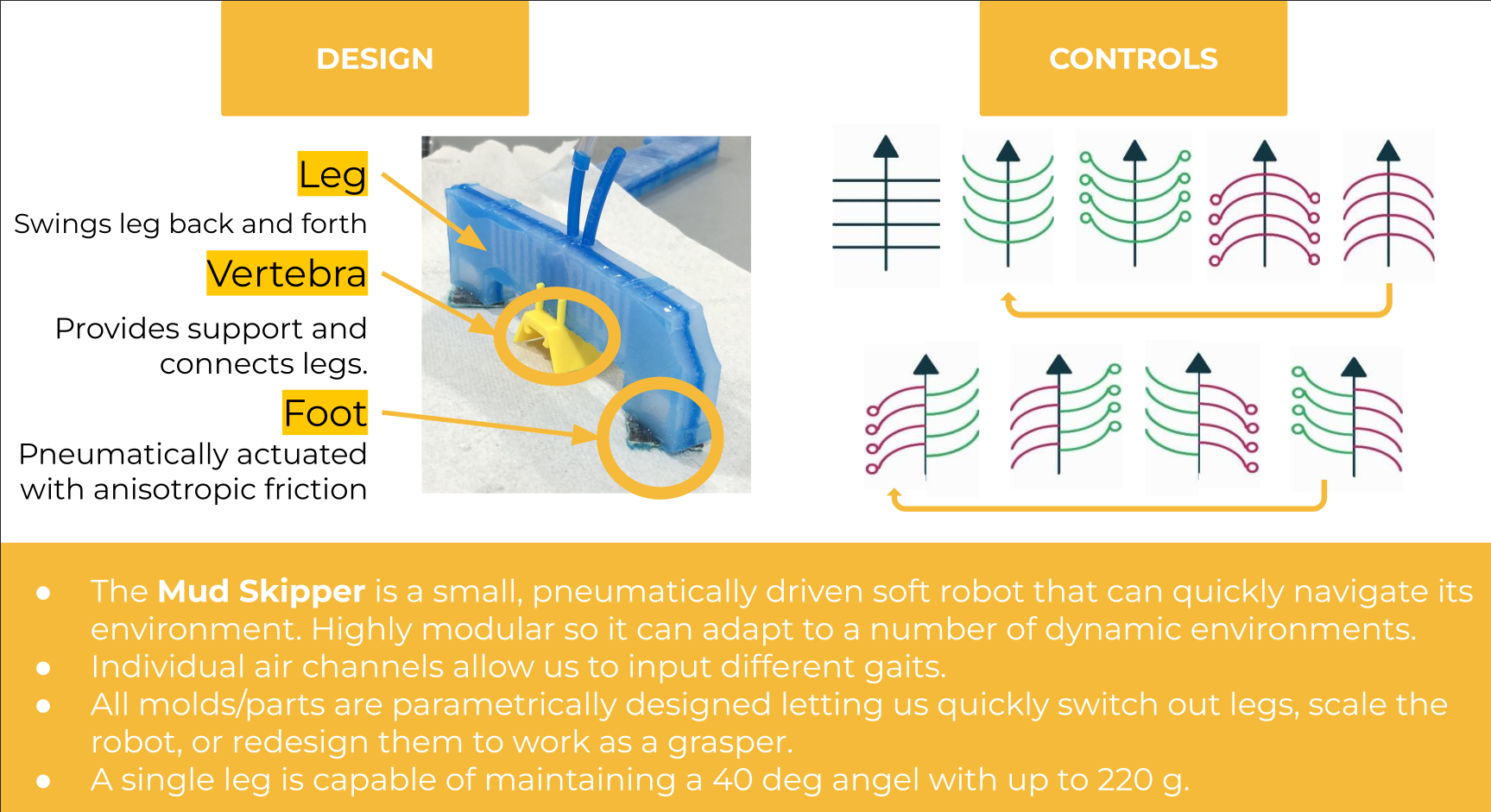

Legs were fabricated using multi-layer silicone casting:

- Outer layers: Dragon Skin 10

- Inner layer: Blue Sapphire Silicone (30A)

- Cured at 70°C in sequential layers to ensure bonding integrity

The design achieved a 40° bend at minimal pressure and enough stiffness to lift the robot over small obstacles.

Two-part mold design for casting Dragon Skin and Blue Sapphire silicone. |  Short clip demonstrating a single leg’s full actuation cycle |

Feet: Anisotropic Friction

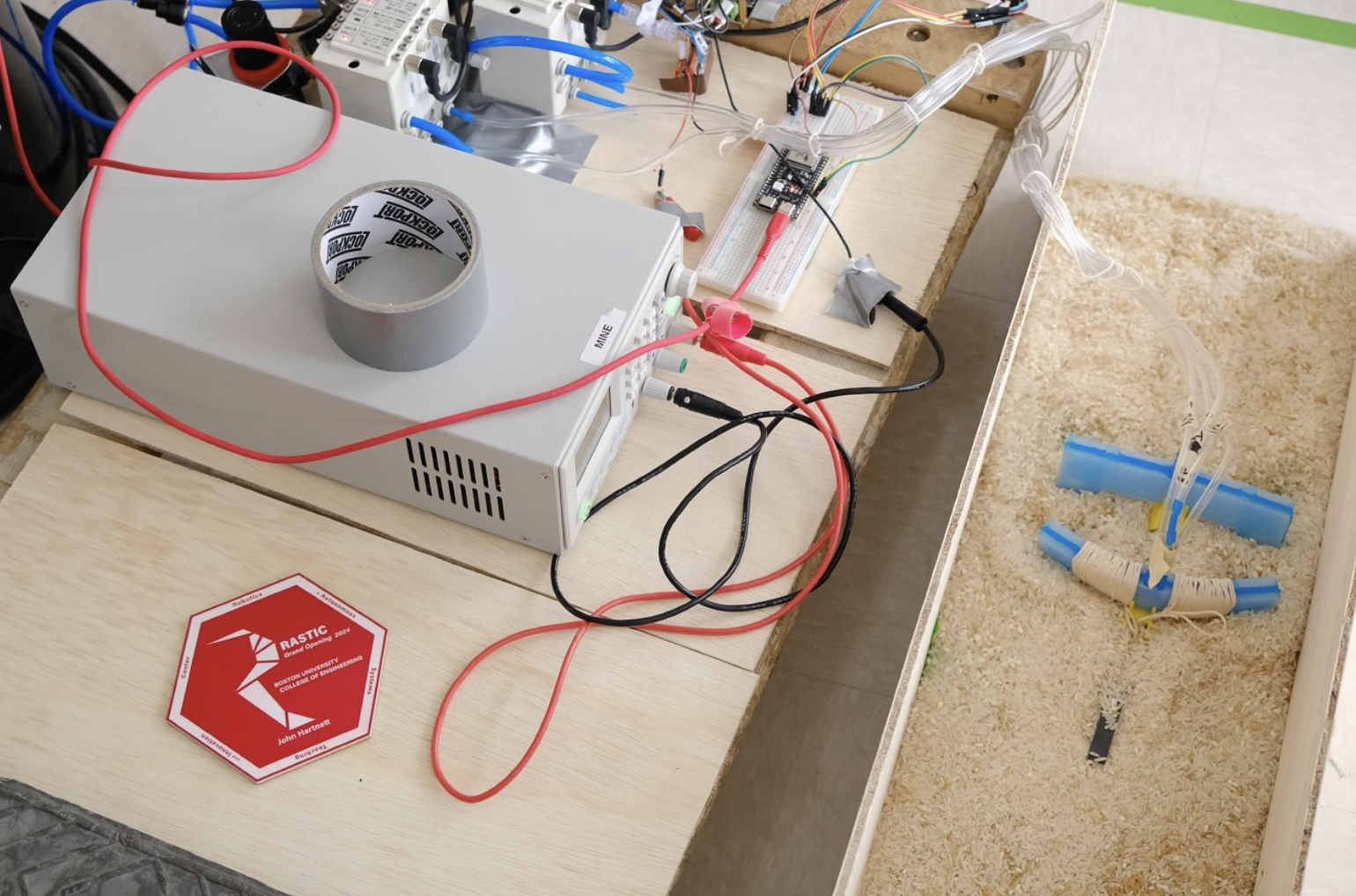

Test on granular media demonstrating anisotropic friction from ski-skin feet.

Test on granular media demonstrating anisotropic friction from ski-skin feet.

Skippy’s most effective configuration used ski-skin as a frictional surface — the same material used for alpine climbing skins.

This yielded a measured friction ratio of μₗ/μₛ = 4.7, enabling smooth forward motion and minimal backslip.

Spine and Vertebra

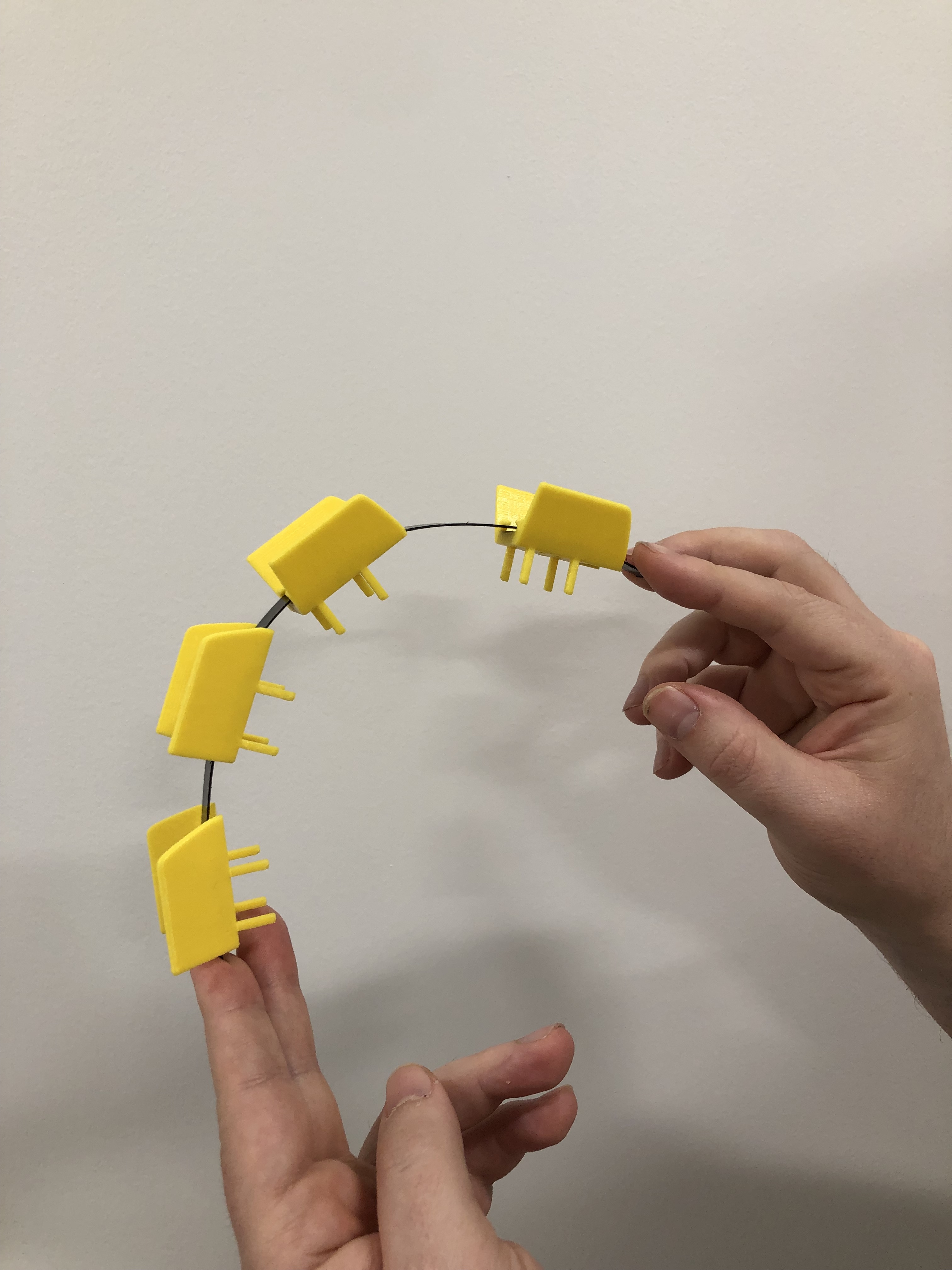

Flexible PLA spine with 3D printed vertebrae for modular leg placement

Flexible PLA spine with 3D printed vertebrae for modular leg placement

The crawler’s body used a repurposed shipping strap as the flexible spine—rigid in one axis and compliant in another.

The vertebrae could slide or be replaced to tune gait spacing for terrain adaptation.

Simulation and Modeling

Abaqus finite-element simulation showing leg deformation under pressure

A finite-element model in Abaqus validated the pneumatic chamber geometry and predicted stress accumulation at channel corners.

Material properties were modeled using Yeoh hyperelastic coefficients for large deformations.

Testing and Performance

Testing included:

- Bending angle vs. pressure – linear relationship confirmed actuator reliability

- Soft resistor feedback – correlated voltage with bending for sensorized control

- Grip test – each leg held 0.86 N before slipping (see below)

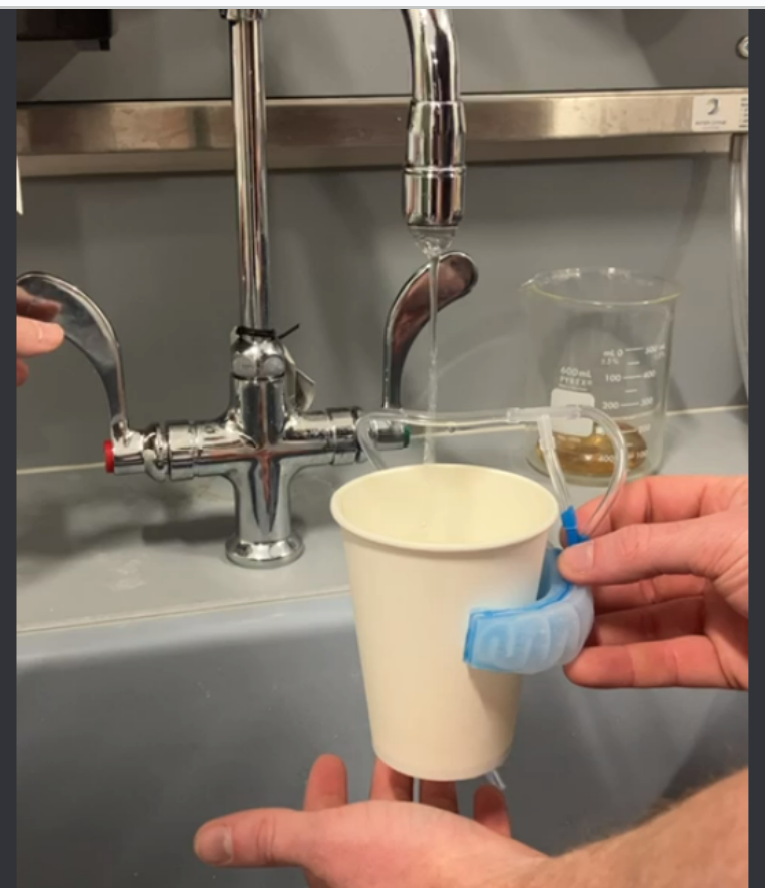

Single leg gripping a loaded cup until slip threshold

Single leg gripping a loaded cup until slip threshold

4-legged competition run for decreased turn radius

4-legged competition run for decreased turn radius

Early testing of Skippy’s movement modes

Early testing of Skippy’s movement modes

Early testing of cyclic pressure limits

Early testing of cyclic pressure limits

Lessons Learned

- Modularity reduced iteration time dramatically.

- Pneumatic consistency mattered more than simulation precision.

- Silicone layer bonding was the most common failure point.

- Embodied intelligence reduced need for control logic.

Future Work

Next-generation improvements include:

- Bi-stable legs for faster motion and reduced air consumption

- Soft vertebrae to eliminate rigid components

- Climbing via cam-inspired mechanisms

- Integration of feedback control for terrain adaptation

Team Skippy post-competition photo

Team Skippy post-competition photo